Flowing Pressure

Water: 40 – 110 psig (2.8 – 7.7 bar)

Syrup (Sugar): 20 – 70 psig (1.4 – 4.9 bar)

Syrup (Diet/Light): 10 – 70 psig (0.7 – 4.9 bar)

Ratio Adjustment Range

3.0-9.0 Water/Syrup by Volume

(dependent on finished drink flow rate)

Electrical

24VAC ±10%, 50/60 Hz

Engineered for Consistent Flavor and Optimal Flow Control

Delivering unmatched reliability and performance, with the lowest life cost.

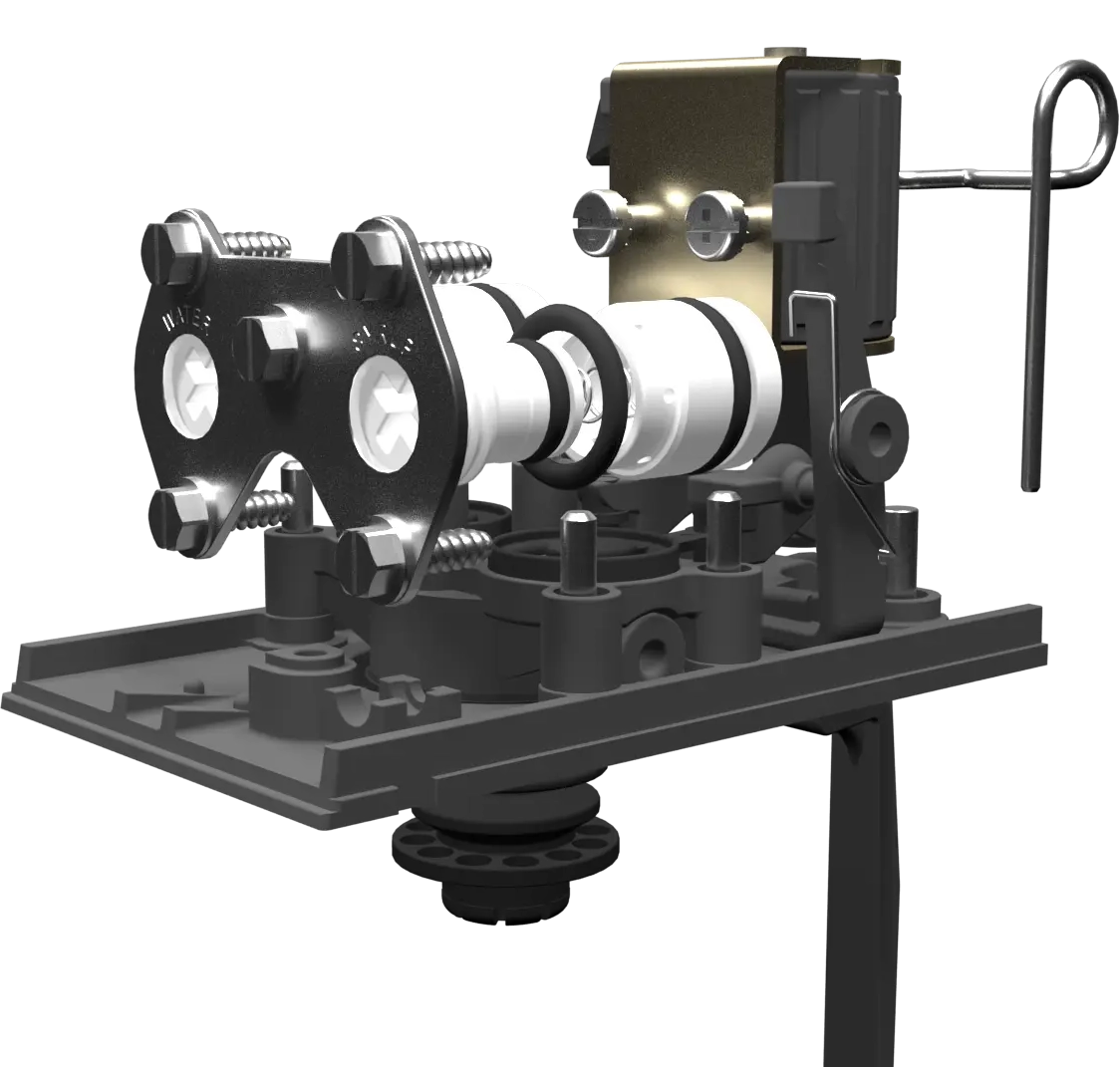

Valve Cover

ID Cover

Solenoid

Retaining Clip

Syrup

Water

Diffuser

Nozzle

Self-Serve Lever

Our valves can maintain stable syrup-to-water ratios, even when operating under fluctuating pressures

LEV valves have undergone comprehensive life cycle and pressure sweep tests, ensuring that they maintain consistent performance even under demanding conditions.

Lancer valves are engineered for durability and have been tested to withstand extensive use, with life-cycle testing simulating up to 10 years of operation. The valves are built to be reliable even in high-volume environments. For warranty and support, Lancer provides technical assistance and quality assurance, ensuring that customers receive ongoing support throughout the valve’s lifespan

Yes, Lancer valves are highly versatile and can handle a wide range of beverage types, including carbonated and non-carbonated drinks, as well as sugar-based and sugar-free syrups. They are designed to maintain precise ratios across various viscosities, ensuring consistent dispensing regardless of the beverage type or flavor.

Regular maintenance of Lancer valves includes periodic cleaning of the nozzle, diffuser, and flow control assemblies to prevent syrup buildup and ensure consistent flow rates. It’s also recommended to perform ratio audits periodically to verify that the syrup-to-water ratio remains accurate. Sanitizing the valves and checking for any wear and tear on components should be part of routine maintenance, ensuring the valve operates efficiently and delivers consistent beverage quality.

Adjusting and maintaining the syrup-to-water ratio is straightforward with Lancer valves. The valves feature adjustable flow controls, allowing for quick calibration to achieve the desired ratio. Additionally, the volumetric valve option is designed to automatically maintain precise ratios once programmed, minimizing the need for manual adjustments. Routine maintenance is simple, with components like the nozzle and diffuser being easy to remove and clean.