The Case for Upgrading your Draft Beverage Program

State-of-the-art draft equipment helps to drive sales, traffic with on-trend specialty beverages.

Like many bar and restaurant operators, you’ve probably taken steps to recover from the pandemic by shortening hours, simplifying the menu, reducing staff and promoting takeout and delivery. But are you missing out on another powerful business-boosting tactic—upgrading your draft beverage system?

A varied selection of on-trend specialty beverages, served quickly, consistently and efficiently with an upgraded draft system, sets your bar or restaurant apart from the competition and invites customers back. After long months of quarantining at home, people are more than eager to return to your premises and sip their favorite drinks again. Meeting their expectations with an impressive beverage menu served with state-of-the-art draft equipment is a vital step in regaining their patronage and restoring your volume.

The modular advantage

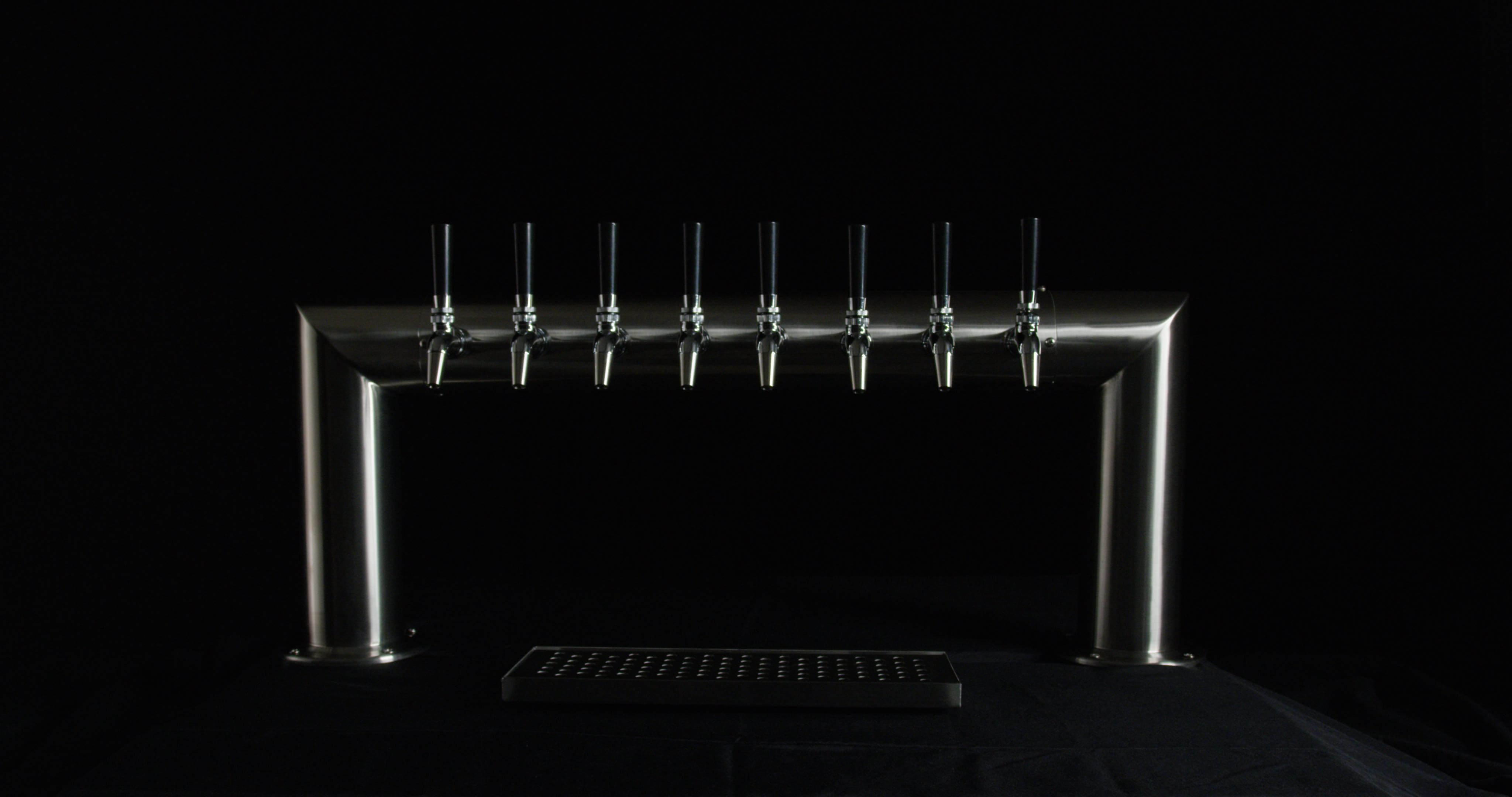

The Lancer™ Worldwide kōld-Draw™ Draft System stands in vivid contrast to the outdated draft equipment many operators are still using. It proves that a draft system can excel in pouring a variety of on-trend beverages in addition to beer, including wine, batched cocktails, cold brew and nitro coffee, tea and kombucha. It does all that in one system with optimum temperature control and greater efficiency and flexibility than competing systems.

The kōld-Draw difference begins with its patented modular cold-block design. It features 360-degree cooling by embedded glycol channels that flow cold glycol through modular cold blocks. This cools a larger surface area with greater energy efficiency and keeps products at proper serving temperature. In addition, the fact that the cold blocks are modular permits quick assembly and changeover of products on the draft tower.

“It is very standard in the industry now to have the ability to serve draft wine on a draft beer tower,” says Phillip Ogle, director of sales at Lancer™ Worldwide. Other common operator “asks” are to run kombucha or coffee on the tower, also easily managed with kōld-Draw’s modular design.

“You can do all of this with a stock Lancer™ tower,” adds Ogle. “This is the only system that can run multiple temperatures with a stock-built tower.”

It should be noted that to provide equivalent flexibility, competing draft systems typically require a custom-built tower, which may cost 10% to 30% more.

Mixing and matching

Given this flexibility, operators can tailor the draft program to match prevailing consumer tastes. For instance, rotating taps of seasonal and local brews delight beer fans. White and red wines come off the tap at controlled temperatures and without the stocking hassles of bottles. Batched cocktails poured on draft are consistent in flavor, and far quicker and easier to serve than mixed-to-order drinks. Draft also allows you to offer nitro coffee, which is increasingly popular with its smoother, less-acidic taste and dramatic cascading appearance in the glass. You can also offer kombucha, the tangy and refreshing fermented tea-based beverage that appeals to health-conscious sippers.

Saving energy

Outdated, inefficient tower cooling designs waste energy and reduce profits. kōld-Draw’s embedded glycol channels create thermal efficiency that complements the glycol chiller and delivers lower cycle rates. This makes for greater energy efficiency even in settings with high ambient temperatures and humidity. In competing draft systems, high ambient temperature warms the faucet and the internal tower components, forcing the system to use more energy to cool.

Not so with the energy-efficient kōld-Draw system. “The purpose of a draft system isn’t to make beer cold, it is to keep it cold,” says Ogle. “Whatever temperature your walk-in is, that’s the temperature you should be serving beer at.”

Ogle sums it up: “The competition might use 5,000 BTUs to cool a draft beer system, but our system might use 3,000 BTUs.”

Quality components

Also noteworthy are the quality materials of the kōld-Draw system, such as 6061 aluminum alloy and full 304 stainless-steel beverage lines, for greater hygiene, purity and durability. Although brass lines are suitable for pouring beer, they can cause off-flavors with acidic products such as coffee and kombucha. For that reason, the kōld-Draw system is free of brass components.

Yet another point of difference in kōld-Draw is the use of PET tubing, which resists flavor transfer, in contrast to the lesser materials that other systems use.

Given the pressing need to welcome back regular customers and attract new ones, there has never been a more critical time for bar and restaurant operators to leverage the power of draft beverages. For more details on how the Lancer™ Worldwide kōld-Draw Draft System can differentiate your bar or restaurant and boost your profitability, visit lancerworldwide.com/kold-draw.