How you can Prevent Foam Waste from Cutting into your Profits

Ever wonder how much profit you’re pouring down the drain with excessive foaming? Find out how foam waste occurs and what you can do to prevent it.

The discipline that goes into brewing the perfect pint of beer is complemented, or not, by the draft system the beer is being poured from. As any bar or restaurant owner will tell you, beer is by far one of the highest margin menu items. Folks who drink beer are very specific about their draft beer. How cold, how much foam is too much or not enough and the type of glass it is served in.

Getting as much beer out of the keg via your draft system is paramount to the bottom line and often foam waste is the culprit of diminished returns when it comes to beer sales.

Foam Waste

Foam is caused by two variables: temperature and pressure. Properly managing your beers’ temperature can be complicated. If the beer is too warm, excess carbon dioxide is released while in the keg and because the pressure is no longer enough to hold the carbonation, foaming occurs. On the other hand, if the beer is too cold, carbonation is held in the beer and not released at all, resulting in over-carbonation, and overfilled glasses. Reducing foam waste is a balancing act between maintaining the right temperature and the proper pressure. Approximately 25% of foam is beer, meaning that 8 ounces of foam is equivalent to 2 ounces of liquid. What does that look like when you translate that into profit?

Clearly, a direct hit to your bottom line. How do you optimize your draft system to reduce foaming and minimize profit loss? There are several ways to optimize your system, however, the most important factor that impacts performance is temperature control.

Here are the top reasons temperature can fluctuate:

• Delivery time of the keg

• Poor refrigeration

• The environment the beer is being served in

• Human error (oops – someone left the refrigerator door open…)

The recommended temperature for draft beer (whether being stored or served) is 38°F. This temperature is optimal for retaining the appropriate amount of carbonation, helping to ensure the right amount of foam. So how do you ensure optimal temperature and reduce foaming?

Take the beer’s temperature

It’s so important to monitor the temperature of your product, as it takes much longer to cool a keg down than it does for that keg to warm up. Place thermometers inside the cooler to get an accurate reading. We recommend placing a glass of liquid inside the cooler and checking the temperature of the liquid several times over several days to ensure you’re getting consistent cooling.

Check the temperature of the liquid as it comes out of the faucet to see if you’re losing cooling in your lines between the keg and the tap. This is where a lot of warming happens in systems that are on the market today. Our kōld-Draw™ Draft System allows for temperature control management at the tap handle.

Keep it clean

Cleaning your beer lines is crucial to ensuring you are not only pouring good product, but also providing longevity for your system. Over time, yeast and sugar can build up in the lines, negatively affecting the taste and contributing to excessive foaming. We recommend cleaning your lines every two weeks. While you can do this yourself, we strongly encourage you to have it done by a professional.

And don’t forget, having a “beer clean” glass to pour your beer into is essential, too. A dirty glass can ruin an otherwise perfect pour as it typically makes the beer look flat. So, keep those glasses clean, too.

Work well under pressure

Make sure you are maintaining the proper CO2 pressure within an acceptable range for the product being dispensed. Your CO2 tank should be stored upright. Improper storage can cause it to not work correctly and can damage your regulator. Also, be sure you are dispensing your product at the right PSI. Most U.S.-manufactured ales and lagers should be dispensed at 10 to 12 PSI, while stout and other nitrogen-dispensed beers should be poured at 30 to 40 PSI.

Evaluate your needs

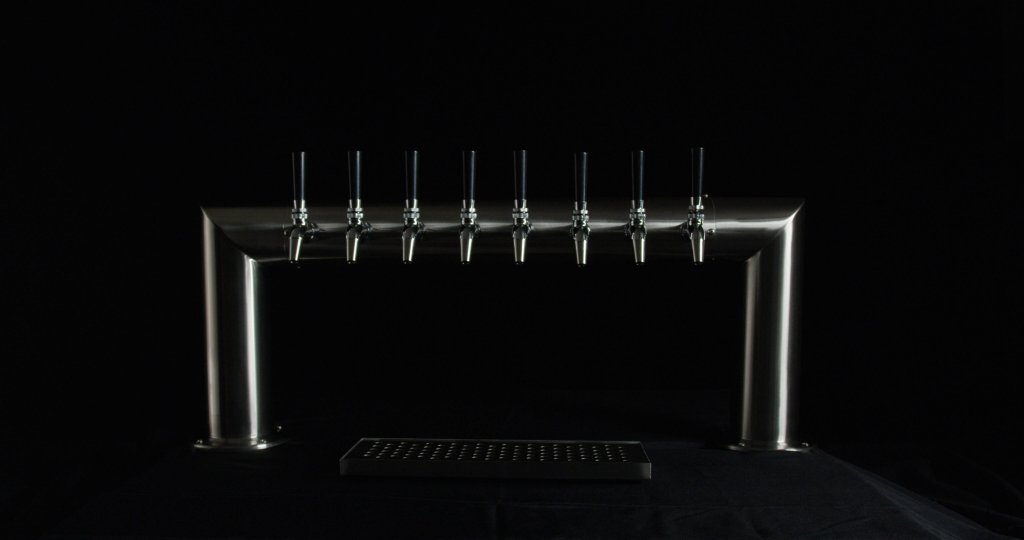

A draft system can provide substantial profit for your business, but ensuring you have the right system to meet your requirements is what matters most. What beverages do you want to offer with your system? What are the varying temperature and storage requirements? Can the system provide everything needed to ensure optimal pours and superior customer service? We know the task of finding the right draft system can be daunting, but we’re here to help you find a system that will meet your needs and the constantly changing needs of your customers. Reach out to one of our experts, or learn more about our kōld-Draw™ Draft Systems today.